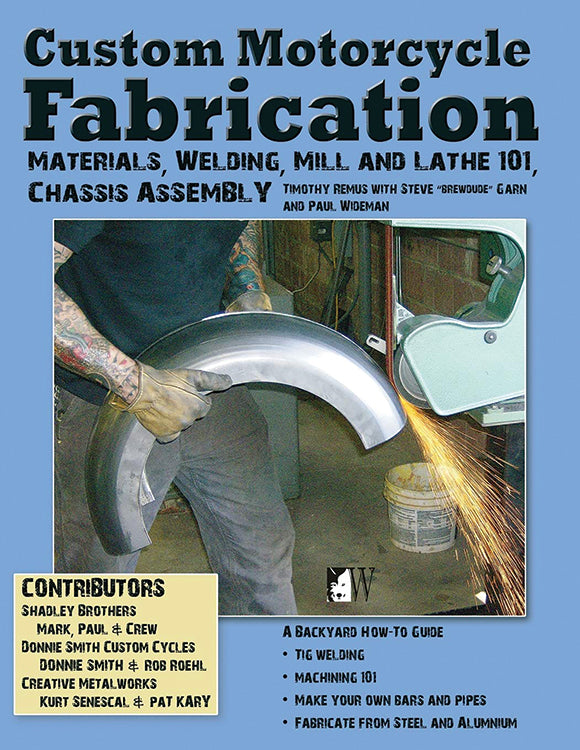

Custom Motorcycle Fabrication

Author: Timothy Remus, Paul Wideman, Steve "Brewdude" Garn

Paperback

144 pages

12410Members save: $6.00 (21.5%)

List Price:

Couldn't load pickup availability

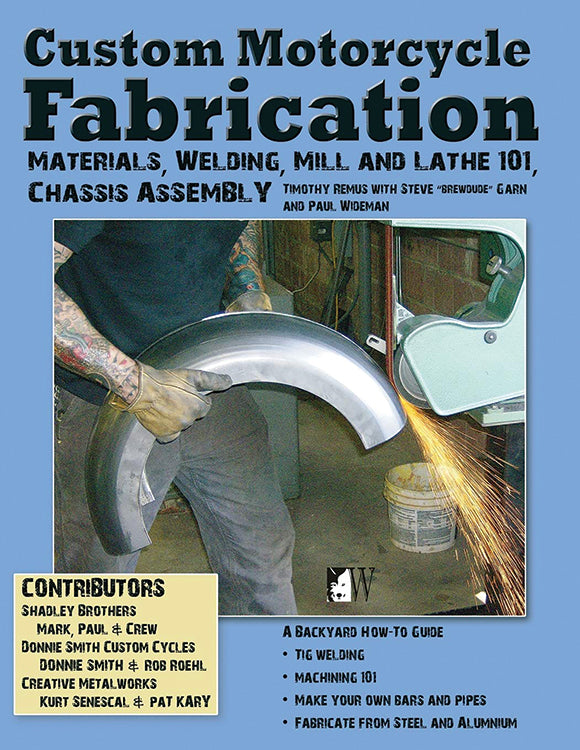

Custom Motorcycle Fabrication starts at the beginning with a discussion of the materials commonly used to fabricate custom motorcycle frames, fenders, brackets, and all the rest. This discussion includes steel, stainless steel, and aluminum.

Joining metal (that is, welding) is an essential part of building almost anything and the copy here includes TIG and MIG welding, as well as Stick and Oxy/Acetylene welding. In each case, the author covers sub topics including penetration, strength, getting started, and the relative size of the heat affected zone.

Most custom motorcycle frames, as well as many of the brackets that hold things together, are made from tubing. Thus, the book includes an entire section on bending and notching tubing to achieve a precise fit between any two parts prior to welding.

A good fabricator must be skilled at machining on both a mill and a lathe. The author walks the reader through the basics for both types of machining: set up, cutting speed, tools, lubrication, cooling, and safety.

Some commonly fabricated parts such as handle bars and exhaust systems are covered as separate topics, along with sections on building simple brackets and mounts.